- Stock: Out Of Stock

- Model: AC511-112-01

- SKU: AC511-112-01

- UPC: 6009515893613

- MPN: 1

More from this brand

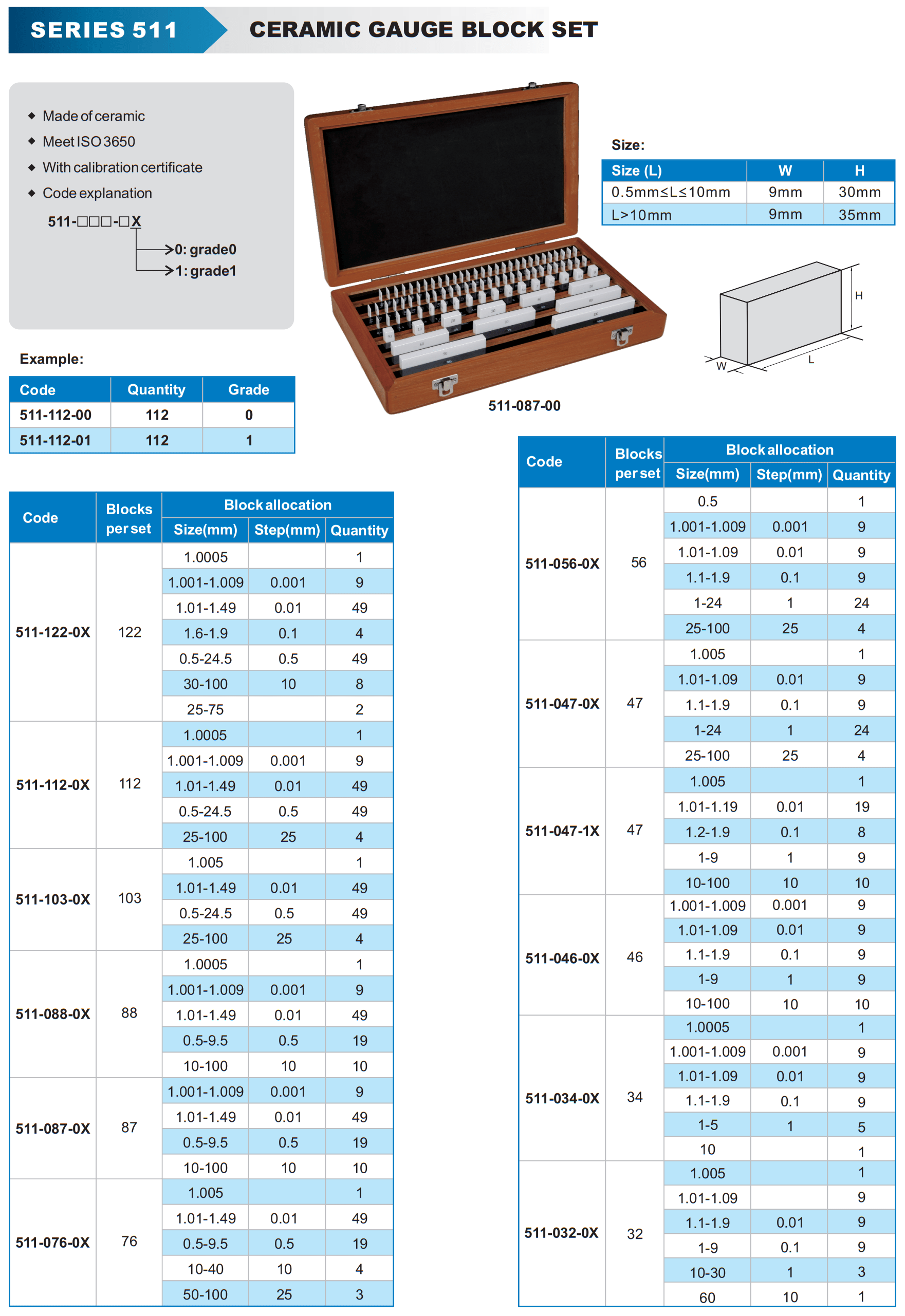

SERIES 511

A ceramic gauge block set is a high-precision tool set used for calibrating and verifying the accuracy of measuring instruments, such as micrometers, calipers, and other precision tools. Gauge blocks are rectangular blocks with extremely accurate and smooth surfaces, which can be combined to form precise lengths. This gauge block set is made from ceramic, being particularly valued for their durability and resistance to wear.

Key Features of a Ceramic Gauge Block Set:

-

Material:

- Ceramic gauge blocks are made from high-grade ceramic materials (typically zirconia-based), which offer several advantages over traditional steel blocks, such as higher resistance to wear, corrosion, and temperature changes.

- They are non-magnetic, which prevents them from attracting metal particles and reduces potential measurement errors caused by magnetic interference.

-

Precision and Accuracy:

- Ceramic gauge blocks are manufactured to very tight tolerances, often in accordance with standards such as ISO 3650 or ASME B89.1.9, which define the allowable deviation for different grades of gauge blocks.

- They are available in different grades that indicate

the level of accuracy:

- Grade 0: Calibration-grade blocks with the highest precision, used for the most demanding applications.

- Grade 1: Inspection-grade blocks, commonly used in quality control environments.

- Grade 2: Workshop-grade blocks, used for setting up and calibrating production tools and machines.

-

Thermal Stability:

- Ceramic blocks have a low thermal expansion coefficient compared to steel blocks, meaning they are less affected by changes in temperature, which helps maintain accuracy in different environments.

- This makes ceramic gauge blocks ideal for use in environments where temperature fluctuations are common, as they experience minimal dimensional changes.

-

Wear Resistance:

- Ceramic blocks are harder and more wear-resistant than steel blocks, giving them a longer service life, especially in high-use environments.

- The surfaces of ceramic blocks are polished to a mirror-like finish, reducing friction during stacking and ensuring precise measurements.

-

Dimensional Range:

- Gauge block sets typically include a variety of blocks with standardized lengths, such as 1.0001 mm, 2 mm, 5 mm, 10 mm, etc.

- The blocks can be combined in different configurations to create a wide range of precise lengths.

-

Wringing:

- The surfaces of the ceramic gauge blocks are extremely flat and smooth, allowing them to be 'wrung' together—this is the process where two gauge blocks are gently slid and pressed against each other, creating a temporary bond without any adhesives. This enables the user to build custom lengths by stacking multiple blocks together with high precision.

-

Non-Corrosive:

- Ceramic gauge blocks are highly resistant to corrosion, unlike steel blocks, which can rust over time if not properly maintained. This makes them ideal for long-term use, especially in humid or challenging environments.

-

Applications:

- Used in calibration labs, quality control departments, and precision machining environments.

- Essential for calibrating and verifying the accuracy of measurement tools like micrometers, calipers, dial indicators, and height gauges.

-

Storage Case:

- A typical ceramic gauge block set comes in a secure storage case, often made of wood or plastic, with individual compartments for each block to protect them from damage and contamination.

Advantages of Ceramic Gauge Blocks Over Steel:

- Wear Resistance: Ceramic gauge blocks are more resistant to wear and maintain their dimensional accuracy longer.

- Non-Corrosive: They are immune to rust and corrosion, even in harsh environments.

- Non-Magnetic: They do not attract metal shavings or debris, ensuring cleaner and more accurate measurements.

- Thermal Stability: They expand less with temperature changes, ensuring greater measurement accuracy in varying conditions.

Typical Use Cases:

- Calibration of precision tools: Used to ensure that tools such as micrometers and calipers provide accurate readings.

- Quality control: Gauge blocks are often used to check tolerances in manufacturing settings.

- Metrology laboratories: Used to maintain precise standards in measurement equipment.

A ceramic gauge block set is essential for ensuring consistent, accurate measurements in high-precision applications, particularly in environments where durability, stability, and resistance to environmental factors are crucial.