- Stock: In Stock

- Model: AC625-000-00

- Weight: 3.28kg

- Dimensions: 135.00cm x 125.00cm x 85.00cm

- SKU: AC625-000-00

- UPC: 6009515842819

- MPN: 1

More from this brand

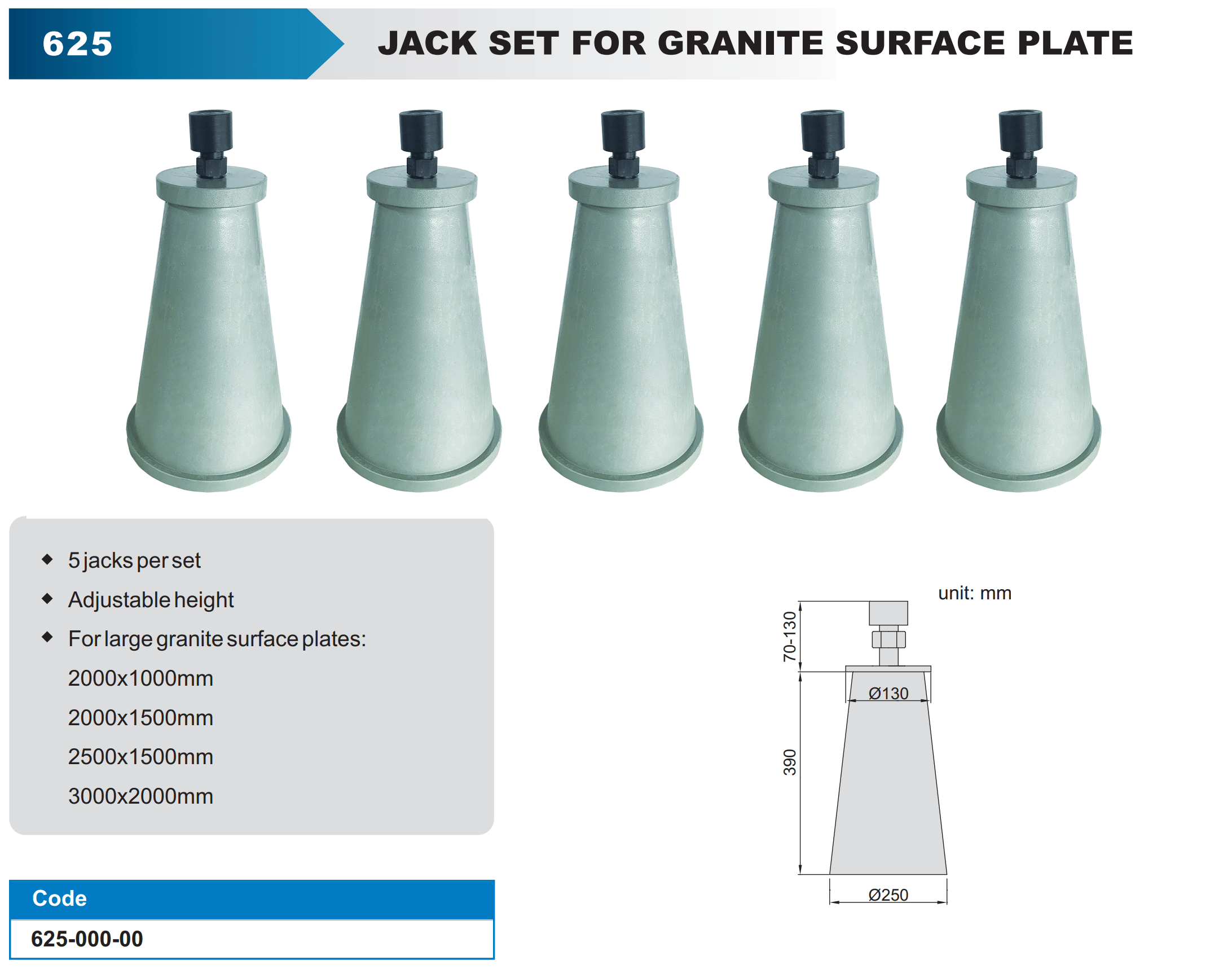

SERIES 625

A 5-piece jack set for a granite surface plate is a specialised tool kit designed to support, level, and adjust large granite surface plates or other heavy machinery. These jacks provide fine-tuned height adjustments and are used to ensure that the granite surface plate remains stable, flat, and level, especially when dealing with larger plates that require multiple points of support.

Functionality of the Jack Set:

-

Leveling the Granite Plate:

- The jacks are placed at strategic points beneath the granite surface plate. The number of jacks used depends on the size and weight of the plate, but for larger plates, five jacks are often required to maintain stability.

- The jacks are adjusted individually to ensure that the plate is level and remains flat across its entire surface. This is essential for ensuring accurate measurement and calibration tasks.

-

Weight Distribution:

- The jacks are positioned to evenly distribute the weight of the granite surface plate, preventing any bending or warping of the plate. This also helps to protect the plate from developing stress points over time.

-

Vibration Dampening:

- The jack set, especially if equipped with vibration-dampening pads, helps to isolate the granite surface plate from floor vibrations or other environmental disturbances. This is important in environments where sensitive measurements are being taken.

How to Use a 5-Piece Jack Set:

-

Placement of Jacks:

- Arrange the five jacks under the surface plate in strategic locations: typically four jacks near the corners and one jack in the center for added support. This ensures even distribution of the weight and maintains the flatness of the plate.

-

Adjusting the Height:

- Use the adjustment mechanism on each jack to raise or lower the height of the surface plate until it is level. A precision level or dial indicator can be used to check the flatness of the plate as adjustments are made.

-

Locking the Height:

- Once the plate is level, lock each jack in place to prevent any movement or settling over time. Ensure that the plate remains securely supported and stable during use.

-

Regular Checks:

- Periodically check the level of the plate, especially if it is subjected to heavy use or environmental changes. If necessary, make slight adjustments to the jacks to maintain the flatness of the surface.

A 5-piece jack set for a granite surface plate is an essential tool for supporting, leveling, and adjusting large granite surface plates. It provides precise control over the plate's height and alignment, ensures even weight distribution, and helps isolate the plate from environmental vibrations. Whether used for installation, calibration, or ongoing support, a jack set is a valuable addition to any workshop or laboratory that uses granite surface plates for precision measurement and inspection.